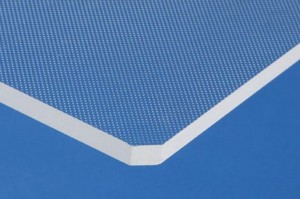

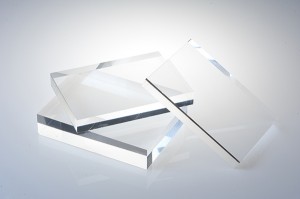

Anti-static sheet

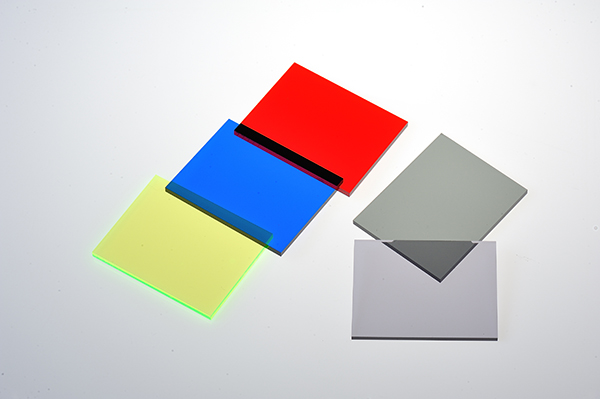

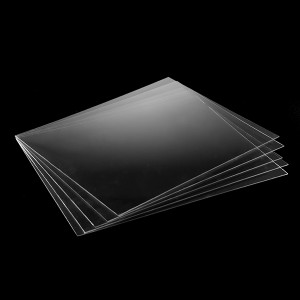

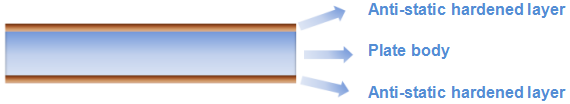

It uses coating technology to form a layer of antistatic Dura mater (very thin, micron, 1 mm mm = 1000 μm um) on the surface of acrylic, PC, PVC and other plates.Anti-static function can last 3 – 5 years, Can effectively prevent the accumulation of dust, To avoid the possible harm caused by static electricity.Anti-static panels are transparent, brown, blue, yellow, etc. (yellow can filter out ultraviolet).

Applications:

Clean room construction (semiconductor, LCD, electronics, optics and medicine, etc.), clean room equipment shelter, clean room space separation, clean equipment, observation windows and equipment hood, electronic test fixture, etc.

Product Features:

① beautiful, light transmittance is over 90%.

② surface resistance value reach 106-108 Ω, excellent anti-static function.

③ excellent surface hardness and scratch resistance, can withstand alcohol and other wipes.

④ anti-static layer can only be removed by mechanical processing methods, anti-chemical solvent erosion, low gas volatility.

⑤ flame retardant grade reach UL-94; HB.

product structure:

Performance parameters:

|

Project |

Test Methods |

Test Results |

|

Transmittance |

More than 90% |

91.5 |

|

Haze |

Less than 1% |

0.2 |

|

Pencil hardness |

Pencil hardness device |

5H or more |

|

Surface resistivity |

Surface deductor |

106-8Ω/cm2 |

|

Cross cut test |

100/100 |

|

|

Thermal shock test |

40℃/45min,85℃/45min,27min |

pass |

|

Heat, humid test |

85℃ 85%RH 72Hours |

pass |

|

Salt water test |

35℃, 5% sodium chloride water for 48 hours |

pass |

Applications: