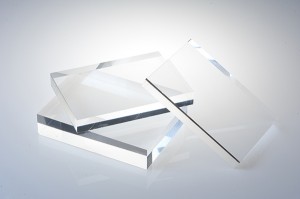

Extruded Acrylic

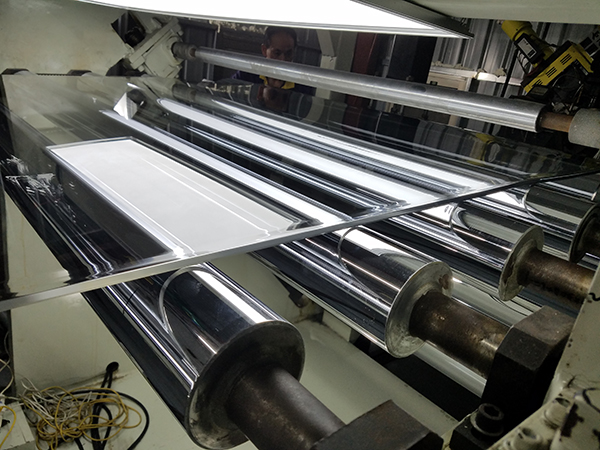

The technology is PMMA (acrylic) particles as raw materials, extruded through the extrusion line production line, compared with the casting plate, the molecular weight of the extruded plate is low, the mechanical properties are weaker. But easier to bend than the casting plate and vacuum plastic molding, and the length of the plate is not limited, flatness is good, the tolerance is minimal.

The kingscope extruded acrylic uses imported optical grade PMMA particles through high-precision extrusion production line production, smooth and bright surface without any crystal point, with stable physical, chemical, optical and electrical properties.

Applications:

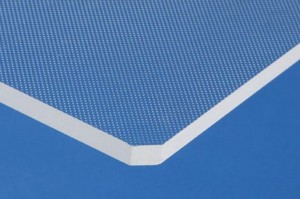

Mainly used for backlight module components, light guide plate, LED panel lights, LCD TV backlight, electrical panels and acrylic products.

Plate Features:

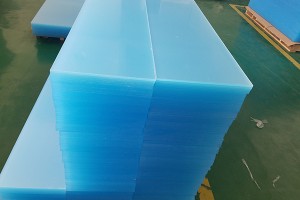

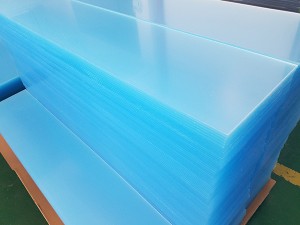

1. With excellent transparency, crystal clear after polished, light transmittance reach 93.4%;

2. Smooth and bright surface, no crystal point;

3. Weather resistant, good temperature resistance, will not fade or dull.

4. Good machining performance, suitable for mechanical processing, also easy thermal forming.

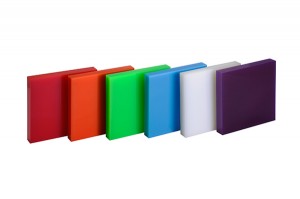

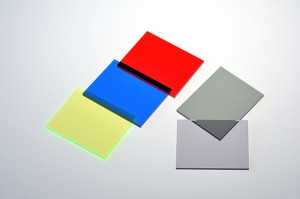

5. Good decoration, suitable for spraying, silk screen, vacuum coating.

6. Light weight, only half weight of the common glass, impact resistance, is 16 times of common glass.

Performance parameters:

|

Project |

Test Results |

Project |

Test Results |

|

Total transmittance% |

93.4 |

Tensile fracture strain % |

6.2 |

|

Rockwell hardness(M) |

93 |

Tensile modulus of elasticity Mpa |

3010 |

|

Heat distortion temperature(1.8MPA) |

98 |

Vicat softening temperature(B50),℃ |

97 |

|

Linear expansion coefficient ℃-1 |

7.0*10-5 |

Anti-solvent opacity(4H) |

no craze |

|

Heating size change(shrink) % |

1.9 |

Beamless impact strengthKJ/M2 |

21.9(C) |

|

Tensile Strength Mpa |

74.7 |

Mold Specifications:

1220*2440mm(Length unlimited, customized)

Applications: