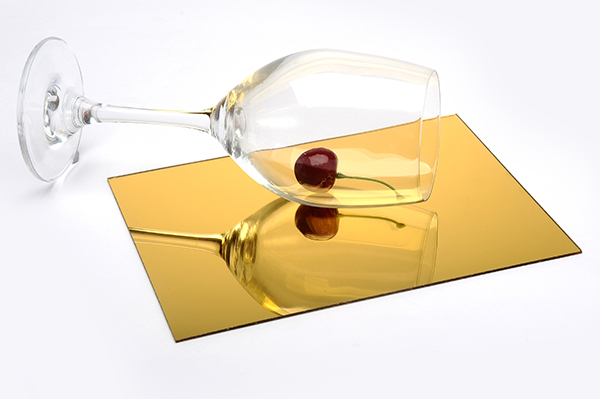

Mirror Sheet

In a high vacuum condition, heating the metal, so that melting, evaporation, cooling in the plastic surface after the formation of metal film, and then through the leaching of paint and a series of processes will form a mirror plate. Generally can be divided into: single mirror, double mirror, with plastic mirror, with paper mirror, semi-lens and so on.

There are two kinds of coating method: one is evaporation coating; the other is vacuum magnetron coating. All kinds of plastic mirror are usually used to evaporate the coating; conventional hardened electronic panels and transparent board with magnetron coating; vacuum magnetically controlled coating of the mirror plate metal strong, high brightness, and environmental protection.

Applications:

Makeup mirror, toy mirror, wide-angle mirror, bathroom mirror, luggage, wall stickers, optical lenses, furniture decoration.

Features:

- Imaging clearly, little crystal point , high surface brightness.

2. Good Flatness , small tolerance.

3. Light weight, only half weight of the common glass, impact resistance, is 16 times of common glass.

Performance parameters:

|

Project |

Test Results |

Project |

Test Results |

|

Total transmittance% |

无 |

Tensile fracture strain % |

6.2 |

|

Rockwell hardness(M) |

90 |

Tensile modulus of elasticity Mpa |

3010 |

|

Heat distortion temperature(1.8MPA) |

95 |

Vicat softening temperature(B50),℃ |

92 |

|

Linear expansion coefficient ℃-1 |

7.0*10-5 |

Anti-solvent opacity(4H) |

no craze |

|

Heating size change(shrink) % |

1.9 |

Beamless impact strength KJ/M2 |

21.9(C) |

|

Tensile Strength Mpa |

74.7 |

Product Specifications:

1220*1830mm 1220*2440mm

Applications: